Metal Sheet Decorating

121 - 1 color Printing Machine

MAILÄNDER 121 – 1 color Printing machine with accessories for max. sheet size: 1150 x 960 mm und max. speed 6500 sheet per hour

KORREX O3 PROOF PRESS

KORREX O3 PROOF PRESS

Max. printing size 720 x 1040mm

Max sheet size 760 x 1060mm

Max. Plate size 820 x 1070mm

Including 1 set of spare rollers Accessories

Sheet Stacker

HEBENSTREIT Sheet Stacker, Year 2011, on Stock

| Maximum Sheet size | 1200x1000 mm |

| Maximum Loading capacity | 3000,0 kg |

Sheet Processing Equipment

Closure Production

Sheet Press for Crown Cork Production

Sheet press for crown cork production.

| Sheet dimension | 811,5 x 573 mm |

| Crowns per sheet | 357 |

| Press output at 172 strokes / min | 2800 pc / min |

| Total power requirement of machine | 9,14 KW |

| Voltage | 380 V |

| Hertz | 50 Hz |

| Compresses air requirements | 500 dm³ / min at 5 bar |

| Machine weight including die set and feeder | 58 kN |

A technician from SACMI inspected the machine for an evaluation of its condition. The report is available upon request.

Sheet Press for Crown Cork Production

Sheet press for crown cork production.

| Crowns per sheet | 729 |

| Sheet size | 1038 x 894 mm |

| Tooling | for short corns 6,10 mm |

| Output: | 242.100 cronws per hour |

A technician from SACMI inspected the machine for an evaluation of its condition. The report is available upon request.

Industrial Chiller

INDUSTRIAL FRIGO chiller overhauled in 2020 available with guarantee suitable for crown cork lining machines.

| Nominal cooling capacity | 122 kW / 105.000 kcal/h |

Aluminium Tube Production

Base Coating Machine

Base coating machine available as spare part stock

Machine will be delivered without the following items:

- control unit

- main drive

- size parts

Slug Tumbler

slug tumbler overhauled with new electrical cabinet

.

Plastic Tube Production

POLYTYPE 6-color printing machine

TEXA packing machine

TEXA BT 2300 Year of manufacturing: 2004

Max. speed: 15 tpm

Max tube length: 200 mm

Tube diameter range: 13,5 – 25 mm

Available tooling: 13,5 mm, 16 mm 19 mm

BREYER MONOLAYER EXTRUSION LINE

With tooling for diameters 30, 35, 40 and 50 mm

Voltage: 380/400V

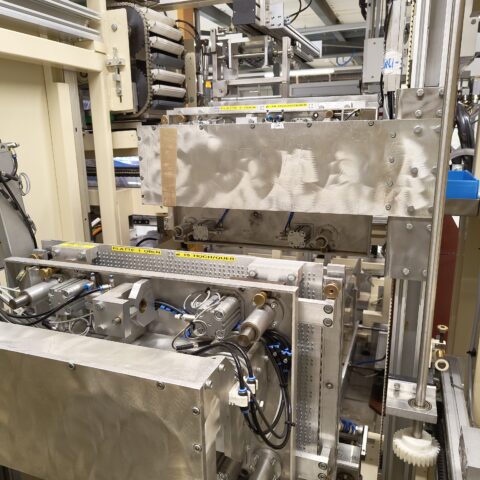

HINTERKOPF DECORATION UNIT

HINTERCOPF DECORATION UNIT

Accumulator S241/1 before Decoration

Hinterkopf DW16/6 printing machine and varnishing system

Thermo oven TE 2806

UV oven TS19

Accumulator S241/1 behind Decoration

Switch cabinets

Transfer unit TD 64 / Chain pitch adapt before and after the printer

The platform supporting the accus and thermal oven

various tools available

HOCHBACH GmbH

Raiffeisenstr. 16

70771 Leinfelden-Echterdingen

Germany

Google Maps

Phone: +49 711 / 9 03 76-0

Fax: +49 711 / 9 03 76-20